Getting The Watry Industries To Work

Getting The Watry Industries To Work

Blog Article

The Buzz on Watry Industries

Table of ContentsSee This Report on Watry IndustriesThe Of Watry IndustriesWatry Industries Fundamentals ExplainedRumored Buzz on Watry IndustriesThe Definitive Guide to Watry IndustriesThe Watry Industries StatementsMore About Watry IndustriesThe Basic Principles Of Watry Industries

((https://comicvine.gamespot.com/profile/w4t8yalumnim/))The Torchmate 4505 is an effective plasma cutter with a 5x5 cutting table. A circulation Industries 4'x4' waterjet cutter solution is offered for sure tasks. Access differs depending upon the part geometry along with the number of parts that require to be cut - Foundry. A spending plan number will need to be supplied for operator/programmer time.

The C15 parking area stays in between both structures. You will need to authorize up for shop safety and security courses before you can access the store. The shop is for working with official UW funded jobs including pupil technical clubs and main research. All store individuals must be an energetic trainees, staff, or professors members of the College of Washington.

Some Of Watry Industries

Participants need to sign up in person, and we advise obtaining in early, since the classes load up extremely rapidly, within a half-hour of being posted. They are held on 3 separate days, each a week apart, and each class is approximately 2 hours long.

If you can not participate in the security classes held throughout a certain quarter, the soonest you will be able to complete them goes to the beginning of the following quarter. Other stores that enable student accessibility besides ours right here on campus: We do not do much help hire any longer, because of the substantial load of pupils we have to monitor, along with other upkeep and shop improvement.

The Single Strategy To Use For Watry Industries

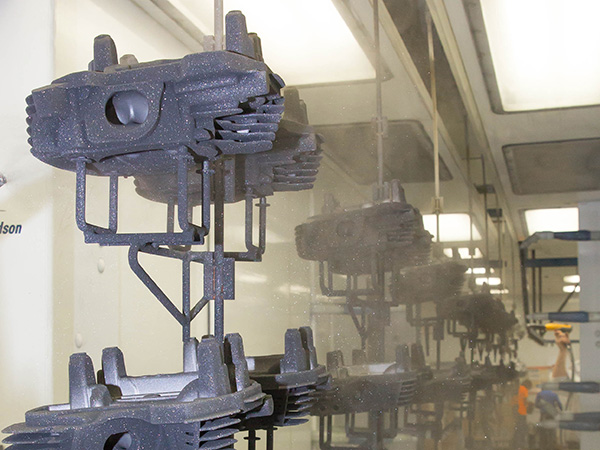

As for gas and vapor power generation, all manufacturing processes require to be function specifically and make up of components and components that can function efficiently under remarkable tension. Valves, such as sphere valves, gate shutoffs, and piston shutoffs, are all steel elements that need making use of CNC machinery. Codes can be configured into the CNC machine and be made use of to make great cuts according to a specific size and weight to support industrial applications.

8 Simple Techniques For Watry Industries

The Shop and its staff concentrate on research and scholastic atmospheres, testing components and constructions of all sizes. Our solutions are available to all divisions in the University of Engineering along with other colleges and academic divisions at the College of South Florida. Design assistance, fixings, manufacture and assembly making use of a variety of materials, consisting of steel, stainless steel, light weight aluminum, plastics and wood Complete complement of contemporary accuracy tooling and machinery, consisting of CNC (Computer Numerical Controlled) machining making use of FeatureCAM CNC software program that can convert SolidWorks and AutoCAD information to meet your layout requires Our shop is fully equipped with numerous welders including TIG, MIG, Stick welders and a Plasma Cutter Our timber shop uses a wide range of woodworking equipment, equipment and hand devices for milling, boring and cutting wood and plastic CNC Milling Machines CNC Turret Manual Milling Machines Guidebook Milling Lathes Surface Area Mill Radial Arm Drill Press Vertical Bandsaw Horizontal Bandsaw Cold Saw Abrasive Cut-Off Saw Oxy-Acetylene Lantern Plasma Cutter TIG Wedler MIG Welder Stick Welder Hand-held Place Welder Shear Bending Brake Beverly Shear Tubing Bender Notcher Drill Press Arbor Press 17.5 Heap Hydraulic Press Buffer Drill Grinder Numerous Manual and Power Hand Devices.

Sadler Equipment Co - Foundry near me. is a very recognized CNC device shop, task store, upkeep, and proto-type machining firm situated in the heartland of America, in Cedar Rapids, Iowa

Machining is an umbrella term that is made use of to produce click to find out more parts by eliminating product from a strong work surface. In the past, machining was typically used for steels, but today it is also utilized for plastics and a selection of various other exotic materials. Machining can include drilling, boring, transforming, reducing, milling, knurling and also grinding to produce the certain needed shape.

What Does Watry Industries Do?

CNC machining is likewise called Computer Numerical Control machining, and it uses the accuracy of a computer system to regulate the certain device and tool in the machining procedure. In this kind of machining, precision is the emphasis, with the tool and the equipment making the precise very same removal of the product from the workpiece with every system.

Rumored Buzz on Watry Industries

Machining. Machining facilities are multifunctional pieces of tools capable of lugging out complex treatments at high production prices. Lathe.

Grinding equipment. A grinding maker is a kind of power device that uses a rough wheel to grind the workpiece. Grinding is normally employed as a completing procedure, since it gives a high surface top quality. Drill press. A drill press is a type of mounted drill whose motion is regulated by a lever.

Bandsaw. A bandsaw is a multi-use cutting equipment utilized to make straight cuts. It is used for about removing sections of product before additional cutting. EDM tools. Electrical Discaharge Machining (EDM) is a process that makes use of sparks as opposed to a physical reducing device to permeate the work surface. Alternative versions of the modern technology use a cable for the device electrode.

Little Known Questions About Watry Industries.

Devices accomplish different production procedures, and may be either hands-on (run by a machinist) or outfitted with Computer Numerical Control (CNC) technology. Equipment, a maker shop might additionally have shops of raw product that can be machined to make components. However, depending on the scale of the manufacturer, materials may be kept somewhere else, in a warehouse for example.

Digital 3D designs are exchanged G-Code, which informs the CNC maker what to do in order to create the 3D shape. Every movement of the reducing tool - Foundry is controlled to millimeter accuracy by the program, which enables the maker to generate ideal duplicate parts to a tright resistance without error

Some makers, such as 5-axis CNC mills, have swiveling pins or tables, which allows the cutting device to cut the block of product from any angle without disturbance. The 5-axis CNC machining technology can maker parts extremely promptly, which is helpful for factory generating large quantities of components for major tasks.

Little Known Questions About Watry Industries.

Additionally, machinists working at CNC maker stores are usually knowledgeable in digital design and for that reason efficient in customizing electronic layouts for CNC machining. Mostly all CNC machinists have experience in manual machining, as this skill helps them better recognize the CNC machining procedure. Furthermore, a CNC factory will normally be qualified of functioning from electronic CAD files, technical drawings or a combination of the two.

Report this page